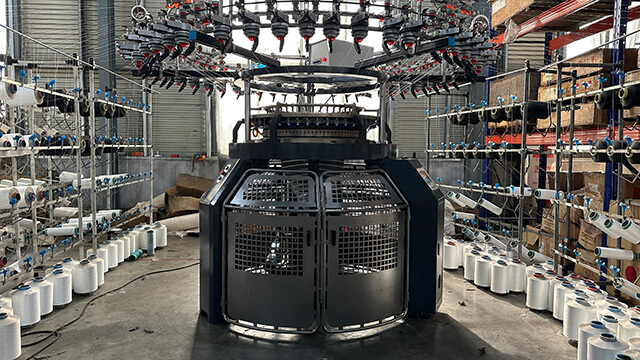

Introduction:In this case , we will explore the successful implementation of a computerized Terry Jacquard Circular Knitting Machine for a client in Thailand. This advanced knitting machine has revolutionized the textile industry by combining innovative technology with traditional knitting techniques. The client, a prominent textile manufacturer in Thailand, sought to enhance their production capabilities and meet the growing demand for high-quality terry fabrics.

Background:The client faced challenges in meeting the increasing demand for terry fabrics due to limitations in their existing machinery. They realized the need for an efficient and versatile knitting machine to produce a wide range of high-quality terry fabrics with intricate designs. After thorough research and assessment, they decided to invest in a computerized Terry Jacquard Circular Knitting Machine.

Implementation:The client partnered with a leading textile machinery supplier to acquire and install the computerized Terry Jacquard Circular Knitting Machine. The supplier provided comprehensive support throughout the implementation process, ensuring smooth integration into the client's existing textile production line. The machine's advanced features, including computerized controls and jacquard capabilities, were tailored to match the client's specific requirements.

Benefits:

1. Enhanced Production Efficiency: The computerized technology enabled seamless control over the knitting process, resulting in increased production speed and efficiency. This allowed the client to meet tight deadlines and cater to bulk orders more effectively.

2. Versatile Design Capabilities: The jacquard functionality of the knitting machine allowed the client to create intricate and personalized designs on terry fabrics. They could now offer a wider variety of products to their customers, gaining a competitive edge in the market.

3. Improved Quality Control: The precision of the computerized controls ensured consistent fabric quality, reducing defects and minimizing waste. The client could deliver products of superior quality, further enhancing their reputation as a reliable textile manufacturer.

4. Cost Savings: The computerized Terry Jacquard Circular Knitting Machine optimized resource utilization, reducing energy consumption and minimizing material waste. This resulted in significant cost savings for the client, contributing to their overall profitability.

Conclusion:The successful implementation of the computerized Terry Jacquard Circular Knitting Machine revolutionized the client's textile production capabilities.

By investing in advanced technology, they were able to overcome their production limitations and meet the increasing demand for high-quality terry fabrics with intricate designs. The partnership with a reputable textile machinery supplier played a crucial role in ensuring a seamless integration process.

This case highlights the importance of adopting innovative solutions to enhance production efficiency, versatility, and quality in the textile industry.

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.