Introduction:This case study highlights the success story of implementing a Single Jersey Circular Knitting Machine for a client in INDIA. The client, a well-established textile manufacturer, was facing challenges in meeting the growing demand for high-quality and efficient knitted fabrics. By adopting the Single Jersey Circular Knitting Machine, the client aimed to enhance productivity, improve fabric quality, and stay competitive in the market.

Challenges which our client meets:

1. Limited production capacity: The existing knitting machines had limitations in meeting the desired volume and efficiency required by the market.

2. Quality concerns: Continuous usage of older machines resulted in inconsistent fabric quality, leading to customer dissatisfaction and increased rejection rates.

3. Rising competition: Competitors with advanced machinery were gaining market share, threatening their market dominance.

Solution:

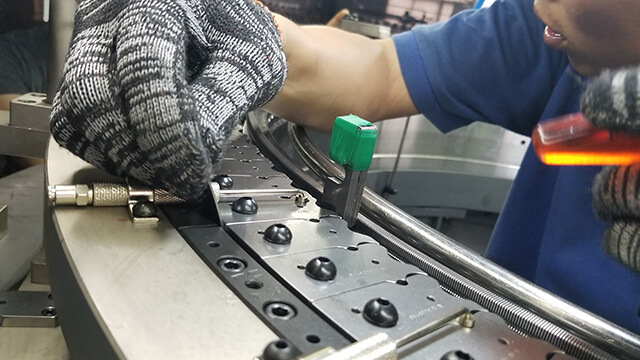

Our client decided to invest in a state-of-the-art Single Jersey Circular Knitting Machine to win the challenges which they have faced. After conducting extensive research and consulting industry experts, they selected our factory which good known for our innovative and reliable machinery.

Benefits:

1. Increased production capacity: The Single Jersey Circular Knitting Machine's advanced technology allowed client to significantly increase their production capacity, meeting market demands and reducing lead times.

2. Enhanced fabric quality: The machine's precise control and superior engineering enabled the production of consistent and high-quality knitted fabrics, resulting in improved customer satisfaction and reduced rejection rates.

3. Cost savings: The machine's energy-efficient design and optimized production processes led to noticeable cost savings in terms of electricity consumption and labor expenses.

4. Competitiveness: With the adoption of modern machinery, our clients regained its competitive edge in the market, attracting new customers and retaining existing ones.

Outcome:The implementation of the Single Jersey Circular Knitting Machine proved to be a game-changer for our client. The company experienced a significant increase in production output, ensuring timely deliveries to customers. The improved fabric quality led to positive customer feedback and repeat orders, strengthening their market position.

Furthermore, the cost savings achieved contributed to improved profitability and sustainability.

Conclusion:This case study demonstrates the successful adoption of the Single Jersey Circular Knitting Machine by our clients in India By investing in advanced technology and addressing their production challenges, the company was able to enhance productivity, improve fabric quality, and regain their competitive advantage.

This example showcases the importance of embracing innovation and investing in modern machinery to thrive in a rapidly evolving industry.

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.