Introduction:

we will explore the successful implementation of a Three Thread Fleece Circular Knitting Machine for a client based in Saudi Arabia. The client, a well-established textile manufacturer, sought to enhance their production capabilities by investing in advanced knitting technology. This case study highlights the challenges faced by the client, the benefits of the solution provided, and the positive outcomes achieved.

Client Background:The client, a leading textile manufacturer in Saudi Arabia, specialized in producing high-quality fleece fabric for various applications. With increasing demand and a desire to improve efficiency, the client recognized the need for a modern knitting machine that could handle the demands of their production line. They approached our company, a renowned provider of textile machinery solutions, seeking expert advice and advanced equipment.

Challenges Faced:The client's existing knitting machines were outdated and lacked the capability to produce the desired fleece fabric efficiently. The outdated machines required frequent maintenance, resulting in downtime and reduced productivity.

Additionally, the client struggled with meeting growing customer demands for customization, as their current machines had limited design flexibility. The client needed a solution that could increase production capacity, improve efficiency, and offer more design options.

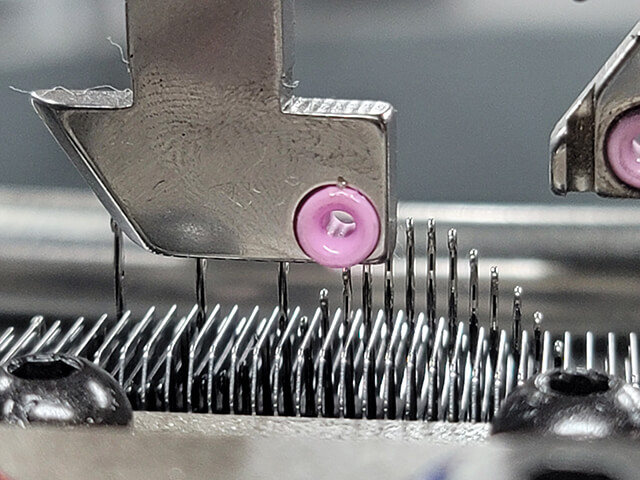

Solution Provided:After thoroughly understanding the client's requirements and challenges, our team recommended the Three Thread Fleece Circular Knitting Machine.

This advanced machine offered numerous benefits, including:

1. Enhanced Productivity: The Three Thread Fleece Circular Knitting Machine featured a higher operating speed and improved efficiency compared to their existing machines. It significantly reduced production time and increased output, allowing the client to meet their growing order volumes.

2. Customization and Design Flexibility: The new machine allowed for a wide range of customization options in terms of fabric weight, color, and patterns. It offered greater design flexibility, enabling the client to cater to the unique preferences of their customers.

3. Reduced Downtime: The Three Thread Fleece Circular Knitting Machine incorporated advanced technology and superior components, reducing the need for frequent maintenance.

This resulted in significantly reduced downtime and increased machine reliability.

Positive Outcomes:Implementing the Three Thread Fleece Circular Knitting Machine yielded several positive outcomes for the client:

1. Improved Efficiency: The new machine streamlined production processes, resulting in improved overall efficiency. It allowed the client to produce more fabric within the same timeframe, significantly increasing their productivity.

2. Enhanced Product Quality: The machine's state-of-the-art technology ensured consistent product quality, meeting the high standards expected by the client's customers. This led to improved customer satisfaction and increased demand for their products.

3. Increased Profitability: With improved efficiency and enhanced product quality, the client experienced a boost in profitability. They were able to secure larger contracts and expand their customer base, further strengthening their position in the market.

Conclusion:The successful implementation of the Three Thread Fleece Circular Knitting Machine provided a comprehensive solution to the challenges faced by our Saudi Arabian client. By investing in advanced knitting technology, the client significantly improved productivity, product quality, and profitability.

This case demonstrates the importance of choosing the right machinery to address manufacturing challenges and unlock growth opportunities in the textile industry.

Tel: +86-18606960861

Tel: +86-18606960861

Email:

Email:

MP/WhatsApp: +86-18606960861

MP/WhatsApp: +86-18606960861

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.