Author:Xingfa Knitting MachineFROM:Circular Knitting Machine Manufacturer TIME:2024-03-12

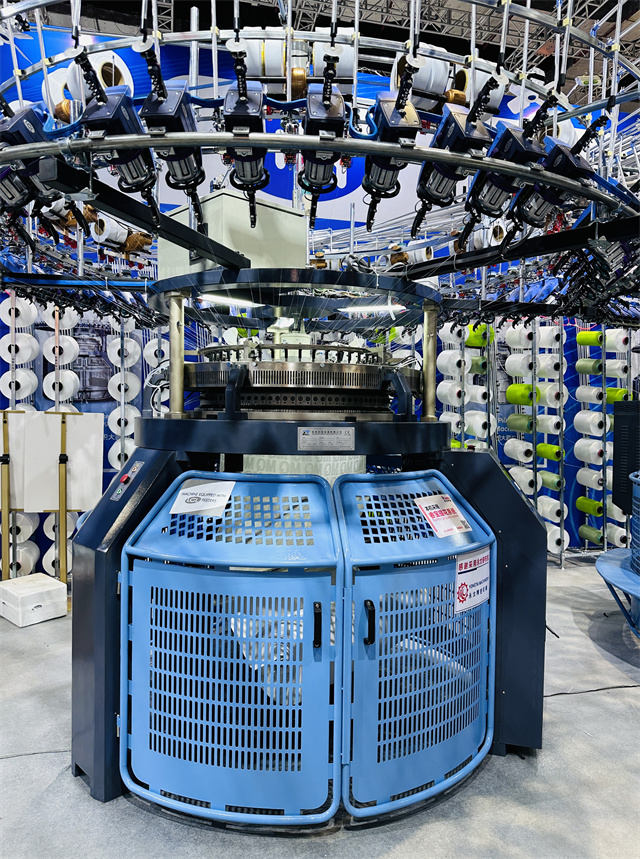

One of the most significant advancements in the textile industry is the evolution of the Terry Jacquard Circular Knitting Machine. This innovative piece of equipment has revolutionized the production of terry fabric, bringing about efficiency, precision, and versatility in the knitting process. The evolution of this machine has not only impacted the manufacturing of textiles but has also contributed to the enhancement of product quality and design possibilities.

The story of the Terry Jacquard Circular Knitting Machine begins with the inception of circular knitting machines. These machines were initially designed to produce basic knit fabrics using a continuous loop of yarn. While they provided a cost-effective and efficient method of textile production, the demand for more complex and intricate fabric designs led to the development of specialized knitting machines.

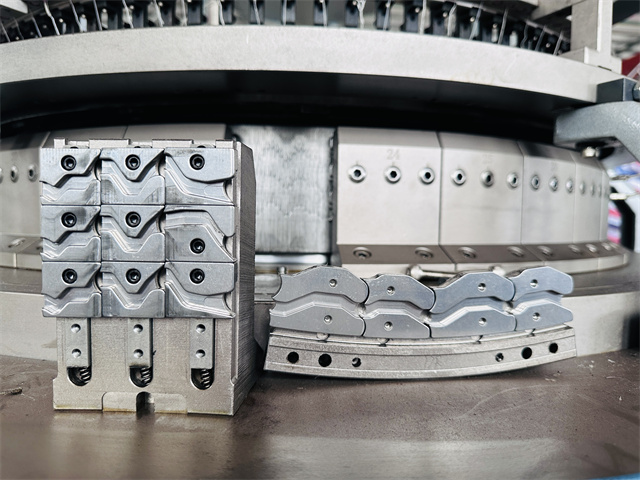

The introduction of Jacquard technology marked a significant milestone in the evolution of circular knitting machines. Jacquard systems made it possible to create intricate patterns and designs by controlling individual needles, allowing for greater flexibility and creativity in fabric production. This technological advancement laid the foundation for the development of the Terry Jacquard Circular Knitting Machine.

With the demand for high-quality terry textiles on the rise, manufacturers sought ways to integrate terry fabric production into circular knitting machines. The integration of terry capabilities into these machines brought about a new era in textile manufacturing, allowing for the efficient and seamless production of terry fabrics with varying pile heights and textures.

To further enhance the capabilities of circular knitting machines for terry fabric production, significant advancements were made in yarn feeding systems. Improved yarn feeding mechanisms enabled the machines to handle a diverse range of yarns, including various fibers and blends, contributing to the versatility and quality of the produced terry fabrics.

The evolution of the Terry Jacquard Circular Knitting Machine also involved the integration of automation and precision engineering. Computerized control systems allowed for precise monitoring and adjustment of knitting parameters, resulting in consistent fabric quality and reduced production variability. Automation streamlined the manufacturing process, increasing overall productivity and efficiency.

As the capabilities of the Terry Jacquard Circular Knitting Machine continued to evolve, designers and manufacturers gained access to enhanced design capabilities. The machines offered greater flexibility for creating intricate terry fabric patterns, textures, and color combinations, empowering the textile industry to meet the constantly evolving demands of fashion and technical textiles.

In line with the growing focus on sustainability, the evolution of the Terry Jacquard Circular Knitting Machine also encompassed environmental considerations. Energy-efficient systems and sustainable manufacturing practices were incorporated into the design of these machines, supporting eco-friendly textile production without compromising on quality or productivity.

As we look to the future, the evolution of the Terry Jacquard Circular Knitting Machine continues to unfold. Ongoing research and development are focused on further enhancing the efficiency, versatility, and sustainability of these machines, as well as exploring the integration of smart technologies for real-time monitoring and optimization of fabric production processes.

In conclusion, the evolution of the Terry Jacquard Circular Knitting Machine has significantly transformed the landscape of terry fabric production. From its inception as a basic circular knitting machine to its current state of advanced automation and design capabilities, this innovative equipment exemplifies the relentless pursuit of progress and excellence in the textile industry. As technology continues to advance, the future holds even greater potential for the evolution of circular knitting machines and their impact on textile manufacturing.

Tel: +86-13533991359

Tel: +86-13533991359

Email: info@xingfamachine.com

Email: info@xingfamachine.com

MP/WhatsApp: +86-13533991359

MP/WhatsApp: +86-13533991359

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.