![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

XF-TM

Model:

XF-TM

![]() NET Weight:

NET Weight:

![]() Diameter:

18’’-52’’

Diameter:

18’’-52’’

![]() Gauge:

7G-28G

Gauge:

7G-28G

![]() Feeder:

36F-104F

Feeder:

36F-104F

![]() Certification:

CE, ISO

Certification:

CE, ISO

![]() Applicable Yarn Material:

Applicable Yarn Material:

![]() RPM:

15-25rpm

RPM:

15-25rpm

![]() Wooden Box Size:

2.25M*2.23M*2.25M

Wooden Box Size:

2.25M*2.23M*2.25M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

![]() Trading Method:

FOB/CIF/EXW Xiamen Port

Trading Method:

FOB/CIF/EXW Xiamen Port

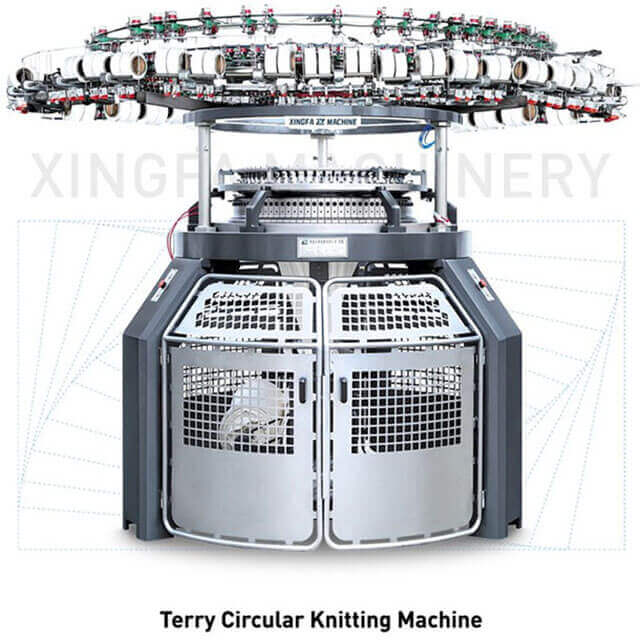

Product Description:

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its advanced technology and versatility. This machine combines the benefits of jacquard technology and circular knitting to create intricate and high-quality terry fabrics.

Technical Features:

1. Jacquard Technology: The Terry Jacquard Circular Knitting Machine is equipped with an advanced jacquard system, allowing for precise control over pattern design and color variations.

2. Circular Knitting Design: With its circular knitting mechanism, this machine enables seamless fabric production, eliminating the need for additional sewing or stitching.

3. Multiple Yarn Feeding: The machine supports multiple yarn feeding systems, enabling the creation of complex patterns and textures.

4. Adjustable Tension Control: The tension control feature ensures consistent fabric quality throughout the entire knitting process.5. User-Friendly Interface: The machine is equipped with an intuitive interface that allows for easy operation and quick pattern setup.

Precautions:

1. Proper Maintenance: Regular cleaning and lubrication are essential to ensure optimum performance and longevity of the machine.

2. Operator Training: Operators should receive thorough training on the machine's operation and maintenance procedures to minimize errors and optimize productivity.

3. Safety Measures: Prior to operation, operators must wear appropriate safety gear and follow all safety guidelines provided by the manufacturer.

INSTRUCTIONS

Latest design for terry machine.

More convenient for worker operation in yarn feeding system.

Offer sinkers for different length of loop as opinion.

Offer more knit cam, tuck cam, miss cam for more terry structures as opinion.

STANDARD SPECIFICATIONS

|

Model |

DIAMETER |

GAUGE |

FEEDER |

LOOP SINKER OPTIONAL |

|

XF-TM |

18’’-52’’ |

7G-28G |

36F-104F |

1.5mm-5.0mm |

|

XF-PM |

28F-84F |

Speed of machine depends on yarm used, kniting condition, gauge etc. So please select proper speed for machine base on different yarn and knitting condition, We give a normal speed guidance as following:

GUIDE SPEED

|

DIAMETER |

GAUGE |

FEEDER |

PRM |

|

24’’ |

18G-22G |

48F/40F |

15-25rpm |

|

30’’ |

60F/48F |

|

|

|

34’’ |

68F/56F |

|

PACKGING&SHIP

|

XF-TM/PM |

34’’DIAMETER |

|

N. W. APPROX |

2.0T |

|

G. W. APPROX |

2.5T |

|

WOODEN BOX SIZE |

2.25M*2.23M*2.25M |

Applications:The Terry Jacquard Circular Knitting Machine finds applications in various industries, including:

1. Fashion and Apparel: It produces high-quality terry fabrics used in bathrobes, towels, bathmats, and other luxury apparel.

2. Home Textiles: The machine creates terry fabrics ideal for blankets, curtains, upholstery, and other home textile applications.

3. Hospitality Sector: It provides the perfect solution for producing premium terry fabrics used in hotels, resorts, and spas.

Main Functions:

1. Customized Design: The machine allows for the creation of personalized and unique terry fabric designs, catering to specific customer requirements.

2. High Efficiency: With its advanced technology and automated processes, the machine ensures efficient and fast production rates.

3. Enhanced Quality: The Terry Jacquard Circular Knitting Machine produces terry fabrics with outstanding texture, softness, and durability.

4. Precision and Accuracy: The jacquard system enables intricate pattern formation with precise color control.In summary, the Terry Jacquard Circular Knitting Machine offers a wide range of technical features, precautions, and applications. Its ability to create customized designs, high efficiency, and exceptional fabric quality make it a valuable asset in the textile industry.

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

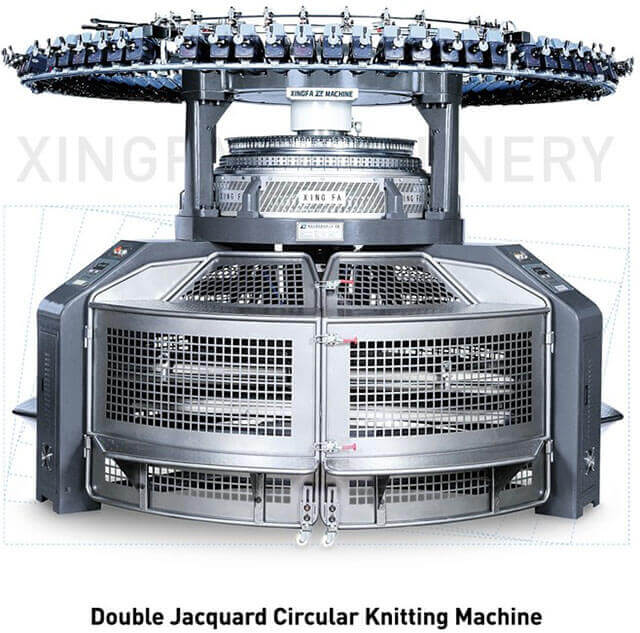

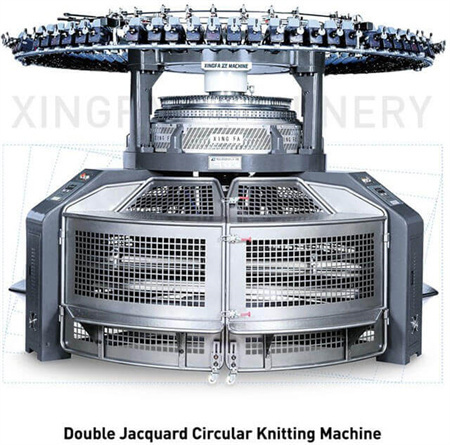

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

Tel: +86-13533991359

Tel: +86-13533991359

Email: info@xingfamachine.com

Email: info@xingfamachine.com

MP/WhatsApp: +86-13533991359

MP/WhatsApp: +86-13533991359

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.