Introduction:

we will explore how our company successfully implemented the Terry Jacquard Circular Knitting Machine for a textile client in Bangladesh. The Terry Jacquard machine is known for its efficiency and versatility in producing high-quality knitted fabrics with intricate patterns.

Client Profile:Our client, a leading textile manufacturer based in Bangladesh, specializes in producing a wide range of knitted fabrics for the fashion and home textiles market. With a commitment to delivering superior quality products, they sought to upgrade their knitting machinery to enhance their production capabilities.

Challenge:The client faced several challenges that prompted them to seek a new knitting machine solution. Their existing knitting machines were outdated and lacked the necessary features to produce complex designs and patterns on terry fabrics. Additionally, the machines were not efficient in terms of productivity and energy consumption.

Solution:

After analyzing the client's requirements, we recommended the Terry Jacquard Circular Knitting Machine. This advanced machine offered numerous advantages, including:

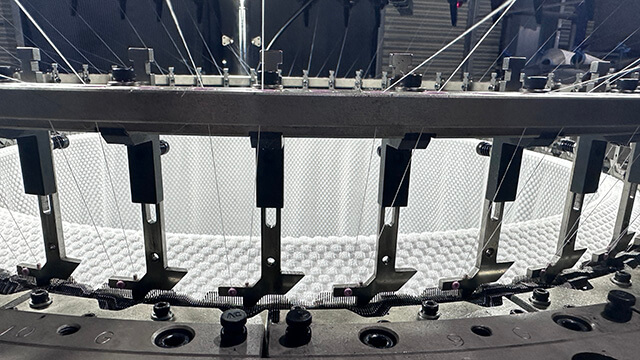

1. Jacquard Technology: The Terry Jacquard machine featured an integrated jacquard system, enabling the creation of intricate patterns and designs on terry fabrics effortlessly. This feature significantly expanded the client's design possibilities.

2. High Productivity: The machine's high-speed operation resulted in increased productivity, allowing the client to meet growing market demand efficiently. The circular knitting technology provided seamless fabric production, reducing downtime and maximizing output.

3. Energy Efficiency: The Terry Jacquard machine was designed with energy-saving features, optimizing power consumption without compromising performance. This aspect aligned with the client's sustainability goals and reduced their operational costs.

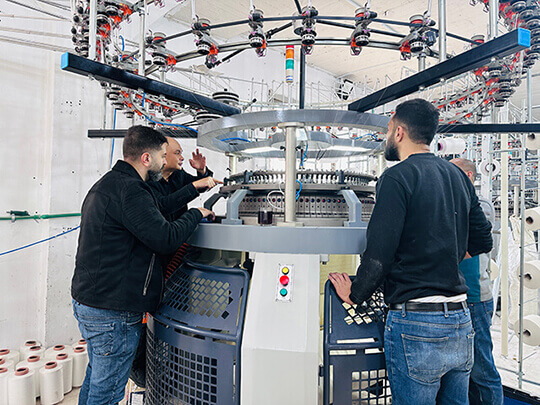

4. User-Friendly Interface: The machine's user-friendly interface facilitated easy operation and swift adaptation for the client's technicians. The intuitive controls and clear display ensured a smooth learning curve and minimized training time.

Results:The implementation of the Terry Jacquard Circular Knitting Machine provided significant benefits for our client. These included:

1. Enhanced Product Quality: The machine's precision and advanced jacquard technology enabled the production of intricate designs and patterns on terry fabrics, resulting in high-quality finished products that met customer expectations.

2. Increased Production Capacity: The high-speed operation of the machine, combined with its circular knitting technology, enabled the client to achieve higher production output in a shorter timeframe. This contributed to meeting market demand promptly and expanding their customer base.

3. Cost and Energy Savings: The energy-efficient design of the machine reduced the client's electricity consumption, resulting in lower operational costs. The improved productivity also led to cost savings by reducing labor requirements and minimizing downtime.

4. Competitive Advantage: With the Terry Jacquard Circular Knitting Machine, our client gained a competitive edge in the textile industry. The ability to produce complex designs and patterns on terry fabrics gave them a unique selling point and positioned them as a leader in their market segment.

Conclusion:The successful implementation of the Terry Jacquard Circular Knitting Machine revolutionized our client's textile production process. By addressing their challenges and providing advanced features, the machine significantly improved their product quality, production capacity, and overall competitiveness in the industry.

This case demonstrates our commitment to delivering innovative solutions tailored to meet the specific needs of our clients.

Tel: +86-13533991359

Tel: +86-13533991359

Email: info@xingfamachine.com

Email: info@xingfamachine.com

MP/WhatsApp: +86-13533991359

MP/WhatsApp: +86-13533991359

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.

Manufacturer Address:B26-1 Taiwanese high-tech industrial base, Luoyang town , Quanzhou city, Fujian PRO. China.